As we mentioned before, there are many factors affect mixing tube wear. Besides the quality of mixing tube itself, orifice quality, concentricity, water quality and mixing chamber also affect nozzle wear.

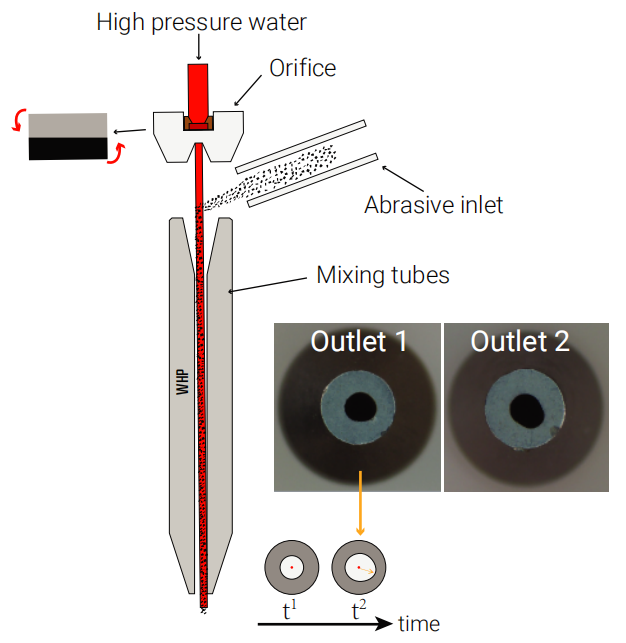

It is very important that the orifice and mixing tube be precisely aligned to ensure a quality, coherent cutting stream by focusing the jet directly down the center of the mixing tube.

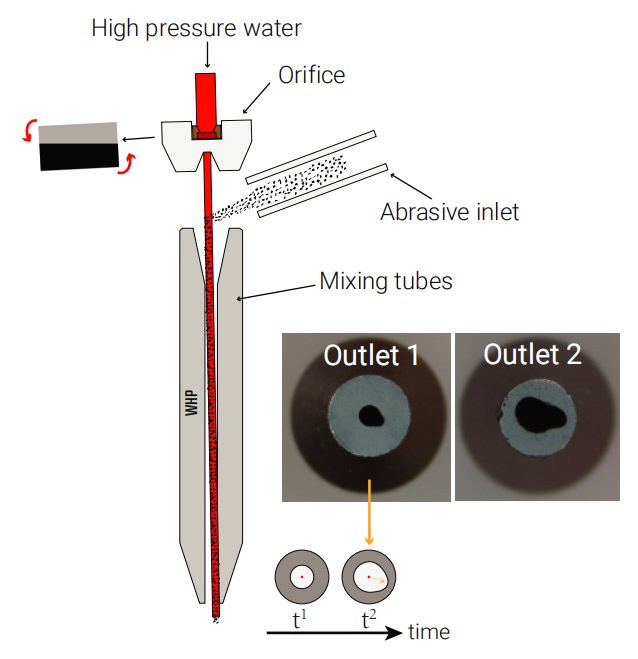

If the jet is misaligned and allows the stream to hit the tube wall, the cut quality will diminish and the tube life will be shortened dramatically

‘In this situation, the service life of mixing tube will be less than normal condition. (When orifice aligned)’

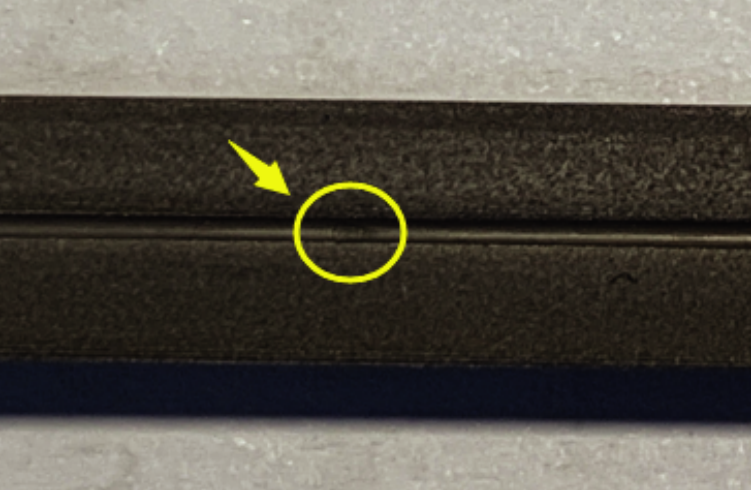

“Misalignment causes deep pockets to be worn into the focusing tube and a ‘tear drop’ shape when viewed from the exit end.”

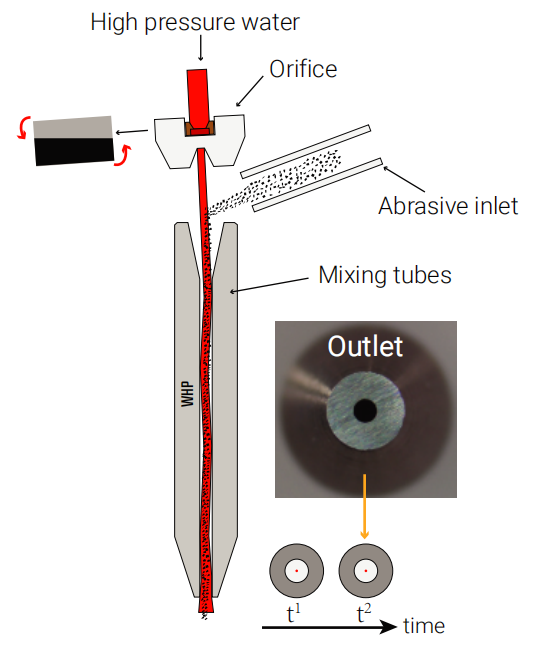

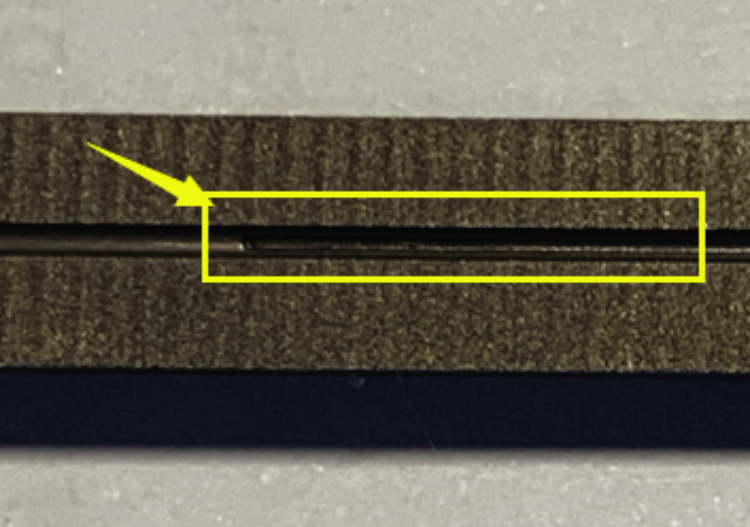

‘Jet which misaligned allows the stream to hit the tube wall at the top half. When the stream arrive at the down half of the tube, it lose most of it’s power. The outlet is almost intact, but the innner wall of the tube is already badly damaged.’ (Figure 3&6)

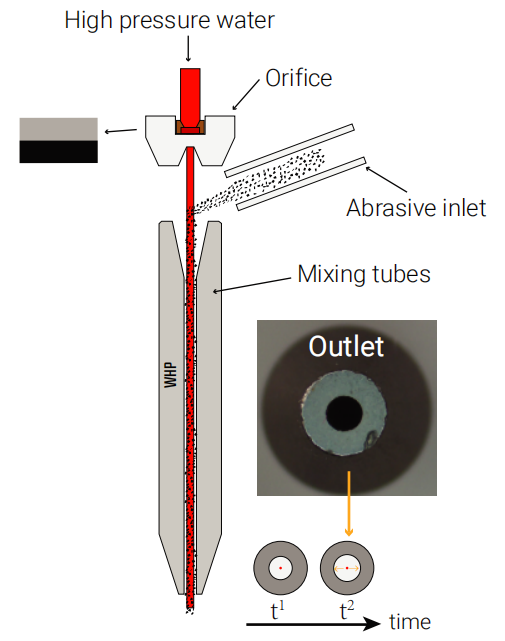

‘The inner wall has impurities or the inner wall is not smooth.The jet stream lose speed when crossing the hole.’ (Figure 7&8)

Good tube/nozzle wear will be concentric and consistent from entry to exit showing a wave like wear pattern ( figure 4, capital 2 ). Mixing tubes with precise alignment will allow the longest life and highest cut quality.

Remember, the longer the mixing tube length, the more difficult the alignment will be, especially for smaller inner diameters.

Miaoke Precision